For Gil Benjamin, the entrepreneurial spirit runs deep. His father blazed a trail in the commercial-vehicle market with a components business called Berrick Industries, which came to be known as FP Diesel (now a DRiV brand) after Fel-Pro acquired the company in the late 1980s.

Inspired by his father’s success, Benjamin set out to carve his own path in the automotive industry.

“I was looking to do something on my own,” Benjamin says. “I grew up in my dad’s business. I knew that I wanted to be an entrepreneur, like my dad, so I looked for any opportunity to start something small in the automotive/heavy-duty markets.”

FP Diesel’s roots were in general spare parts for American diesel engines. Although the company operated in the heavy-duty space, Benjamin saw an opportunity to leverage his knowledge and contacts to start a components business in the light-duty market.

“I got a lot of market information – not just from the guys who were assembling the water pumps, but from the customers themselves,” says Benjamin. “It was just an easy fit. I could put the puzzle together before I actually pulled the trigger.”

Benjamin’s entrepreneurial journey began in 1995 when he and his cousin, Doron Goren, acquired a small water-pump assembly plant in New Brunswick, New Jersey.

“We literally took all the parts, manufacturing presses and an old forklift, loaded everything into two 40-foot containers and shipped them across the U.S. to City of Commerce, California,” Benjamin recalls.

That acquisition marked the inception of US Motor Works.

“It was literally two manual presses with some parts and knowhow of how to build water pumps in a small warehouse that was assembling approximately 25 different domestic SKUs for a handful of customers in Puerto Rico and Venezuela,” adds Benjamin, who is president and CEO of the company today.

Humble Beginnings

Until 1999, US Motor Works (USMW) focused on assembling and distributing water pumps for the automotive and heavy-duty industries, mostly through private-label customers. In the early days, as Benjamin remembers it, the company’s roster consisted of Benjamin, Goren (now the COO), a secretary “and two guys in the back putting pumps together.”

From the outset, the company’s differentiator was its emphasis – or laser focus, rather – on producing a quality water pump.

“We knew water pumps better than anyone,” says Benjamin. “If anybody wanted to know anything about water pumps, we had the knowhow. We started at the engineering level of it, the design level of it, to try to understand what makes a superior water pump. Today, we sell our water pumps with features that we think are critical, like case-hardened bearings.”

Production ramped up quickly. By 1997, US Motor Works was producing 30,000 water pumps a month. Two years later, the company expanded into a 30,000-square-foot manufacturing facility in Cerritos, California. By 2007, USMW was making approximately 1 million water pumps a year, after tacking on an additional 20,000 square feet of production space at its

main factory.

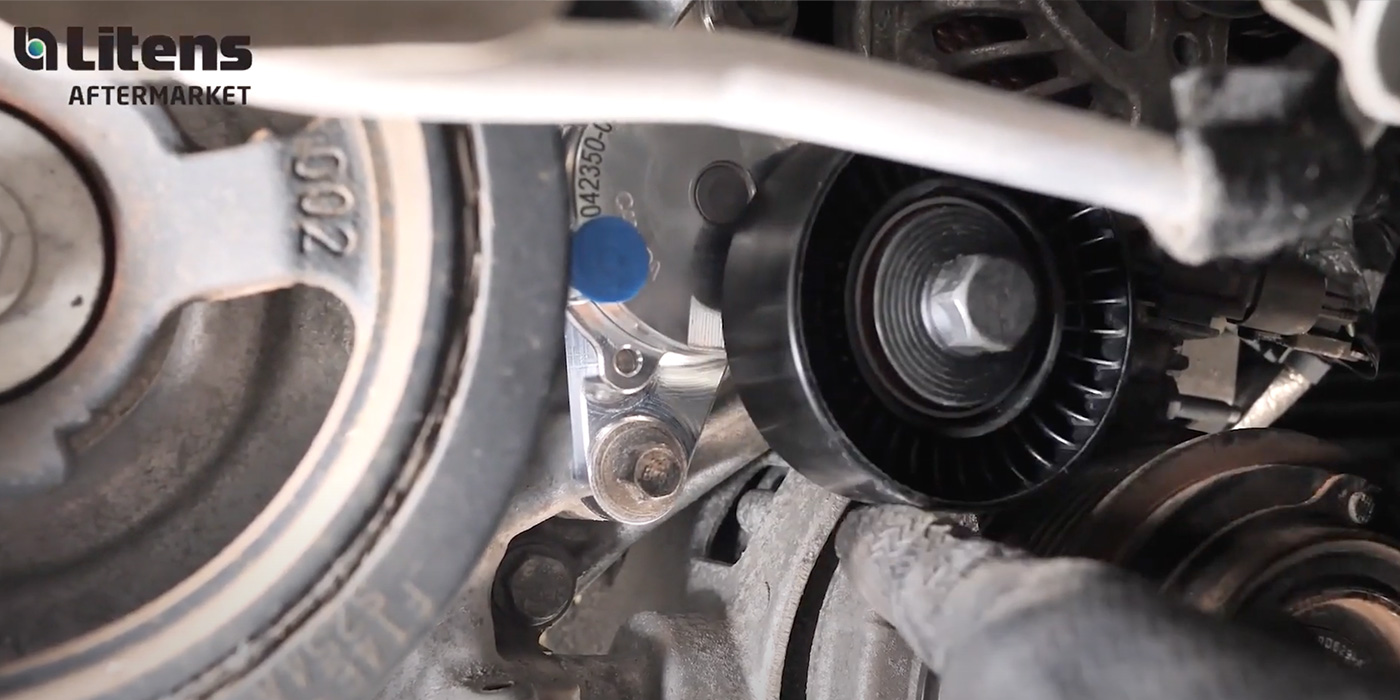

From its humble beginnings in 1995, USMW has evolved into a leader in the cooling segment of the automotive and heavy-duty markets. Today, the product portfolio includes mechanical and electric water pumps, fan clutches, radiators, condensers, heater cores, charge-air coolers, fluid coolers, electric fans, belt-driven fans and a complete line of fuel systems.

The company expanded into fan clutches with an acquisition in 1999. According to Benjamin, US Motor Works was the first company to introduce water-pump/fan-clutch kits, which now are “a must-have item in every store.” He adds: “We are at the forefront of cataloging, kitting, educating and bringing new products to the market.”

Global Reach

Today, US Motor Works is headquartered in Santa Fe Springs, California. While most of the company’s sales come from North America, it wasn’t always that way. In fact, during the early years, USMW primarily sold to customers in Latin America and the Middle East.

“As opposed to most American companies that grow within the U.S. and then start exporting out to other countries, we started in other countries and entered into the United States,” Benjamin explains.

Today, USMW still has a strong international presence that complements its core North American business. In 2019, the company opened a 50,000-square-foot distribution facility in Monterrey, Mexico. Two years later, USMW built an 85,000-square-foot manufacturing facility on the same campus. The facilities serve as a manufacturing and distribution point for Mexico, Central America, South America and other countries. They also gave USMW the ability to “nearshore our high-velocity items to be able to bypass any interruptions with the supply chain.”

“We are very happy with that decision, as we already had the DC there to support our customers – with management and employees in place,” Benjamin says. “It made all the sense in the world to add the manufacturing facility next door.”

Benjamin points to the decision as an example of what he considers a key competitive advantage for a privately owned firm such as USMW: the ability to pivot and make decisions without wading through layers of bureaucracy.

“We are fast at decision-making, we are fast in implementing, we are fast in just about everything we do,” asserts Benjamin. “Since we aren’t reporting to anyone, we can decide, implement, measure, test and – if we need to – pivot. This gives us an enormous competitive advantage in every aspect of the business.”

Benjamin points out that USMW is in the process of adding a 45,000-square-foot facility to its Monterrey campus.

A Firm Foundation

In addition to its corporate offices in Santa Fe Springs, US Motor Works operates a manufacturing and distribution facility in Los Angeles; a fulfilment center in Duluth, Georgia; a new fulfillment center in Liberty, Missouri; and the aforementioned manufacturing and distribution facilities in Mexico.

Several of those facilities have earned ISO 9001:2015 certification, and the facilities in Mexico are in the process of getting certified, according to Benjamin. US Motor Works first earned ISO certification in 2010, and Benjamin asserts that ISO quality standards are “the backbone of our operations and processes.”

ISO certification falls under the larger umbrella of operational excellence – OPEX for short – which the company has codified as “a business philosophy aimed to achieve a sustainable competitive advantage.” USMW considers lean manufacturing and continuous improvement to be the foundation of its OPEX approach, with an overarching focus on meeting the customer’s needs through teamwork, optimized processes, empowered employees, collaboration and problem-solving principles.

Continuous improvement, Benjamin explains, is a mindset that permeates every aspect of USMW’s day-to-day operations.

“Everybody has the same mentality of, ‘What can we do better? How can we improve things? How can we pull an order faster? How can we put away an order faster.’ I would say [continuous improvement] is all-encompassing.”

In more concrete terms, continuous improvement has helped the company reduce lead times and response times while achieving “best-in-class” on-time delivery rates, reduce its overall costs and maintain high levels of product quality, according to USMW.

USMW’s strong foundation of operational excellence enables the company to be on the leading edge of product development. The company said it places a premium on being first to market – a critical factor in maintaining its competitive edge in the automotive aftermarket.

From product definition to design, production planning and preparations, prototype production and final production run, US Motor Works has the capability to bring a product to market in 120 days or less. USMW said this 120-day product-development cycle is a testament to its agile decision-making structure, streamlined processes and optimized workflows.

“We have the ability to react very quickly, and if you put it into the context of product development, we know where the trigger points are to begin the purchasing of OEM items and begin the process of reverse engineering,” Benjamin explains. “We at USMW don’t just reverse-engineer. We also have a database that tells us if the OEMs are reporting any issues out of the ordinary with that part in the field, and if so, we try to find an enhancement that can solve a known OE issue. This is part of our continual-improvement plan within the product-development process.”

The rapid turnaround time enables US Motor Works to continually introduce innovative products that address the evolving needs of the automotive and heavy-duty markets. However, Benjamin emphases that the first-to-market philosophy “isn’t just about speed.”

Adds Benjamin: “It’s about delivering the right products at the right time with the highest quality.”

The Road Ahead

While much of USMW’s growth has come organically, a few key acquisitions have turbocharged its momentum over the years. In addition to the aforementioned fan-clutch acquisition in 1999, USMW acquired Derale Performance and Pacer Performance in 2016, and OSC Automotive in 2021.

Benjamin notes that each acquisition has been “strategic and within our spectrum of expertise, as we tried to stay focused on the cooling side of the business.”

Going forward, USMW will continue to focus on growing organically while being open to bolt-on acquisitions that expand or complement its existing portfolio, he adds.

“For us, it’s very important in an acquisition for the company to have the same culture,” Benjamin explains. “We feel that the most important part of any organization are the people who run it day to day. If we decide to acquire a company, our intention is to keep the people who brought the company to where it is today. We don’t want to change it; we want to bring our expertise to enhance it and with our mutual synergies and learned experiences and expertise.”

USMW’s story over the past three decades isn’t so much about organic vs. external growth – it’s about growth, period. The company’s timeline is dotted with numerous milestones and expansions, the latest of which is a 167,000-square-foot fulfillment center that USMW opened in Liberty, Missouri, earlier this year. The company purchased the facility to centralize its distribution, expand its fulfillment capabilities and accelerate delivery times – and it’s already operating at full capacity.

It’s safe to say business is booming. To meet the ever-growing demand for its products. USMW is in the process of building a 100,000-square-foot distribution center next door.

Due to the facility’s strategic location, “we are two days or less away from 85% of anywhere in the country by truck,” Benjamin says. “This new fulfillment center will not only allow us to serve our customers better, but it will also allow our products and brands to continue growing without space limitations.”